Kunb Single Column Oil Immersed Transformer

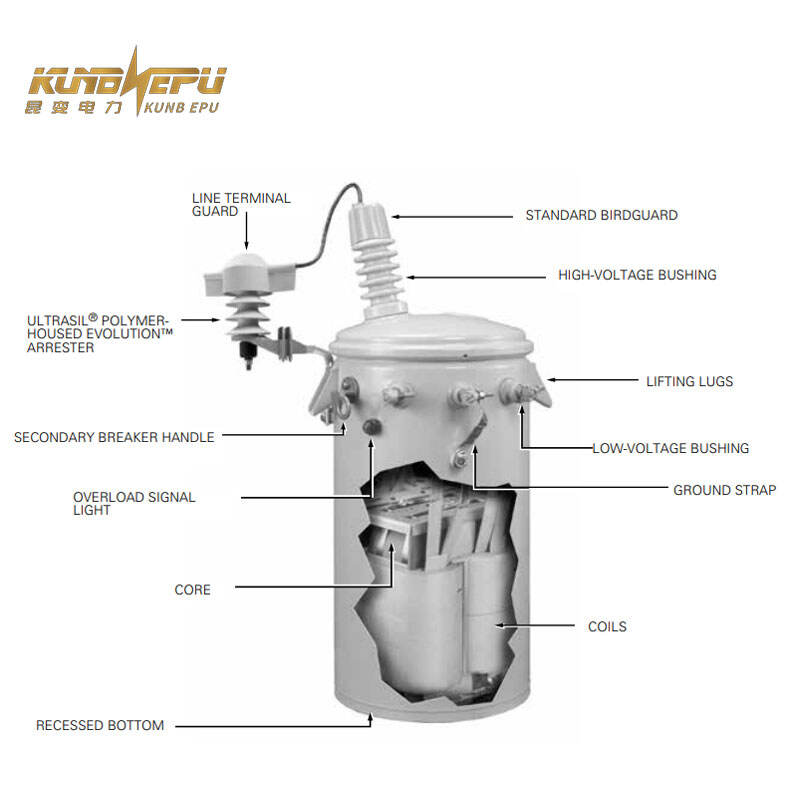

A single-phase oil-immersed transformer is a widely used electrical device designed for voltage step-up and step-down applications. Unlike three-phase transformers, which require three-phase power supply systems, single-phase transformers are ideal for smaller, single-phase systems or where three-phase power is not available. They offer a more compact and cost-effective solution for residential, commercial, and small industrial applications. The transformer consists of an iron core, and the oil inside the tank serves both as a coolant and insulator, ensuring safe and efficient operation. Single-phase oil-immersed transformers are easier to install, require less maintenance, and are typically more affordable than their three-phase counterparts. These advantages make them an excellent choice for localized power distribution, particularly in areas with lower power demands or where three-phase power is not essential.

Description

Product Description

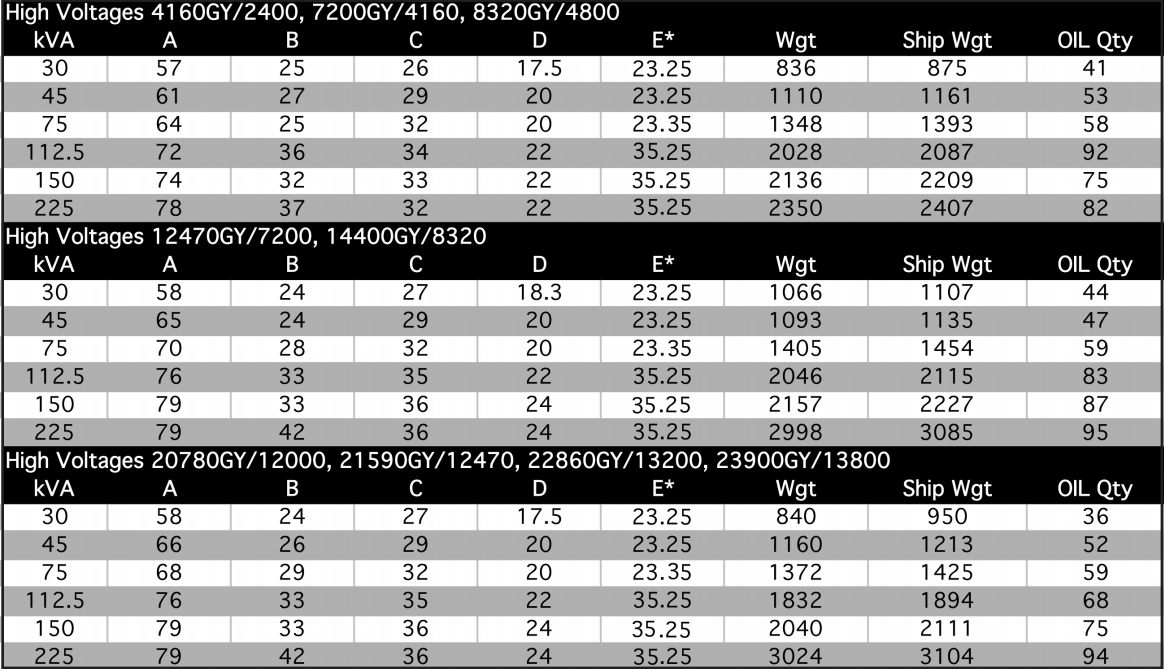

Product Parameter

Product Advantages

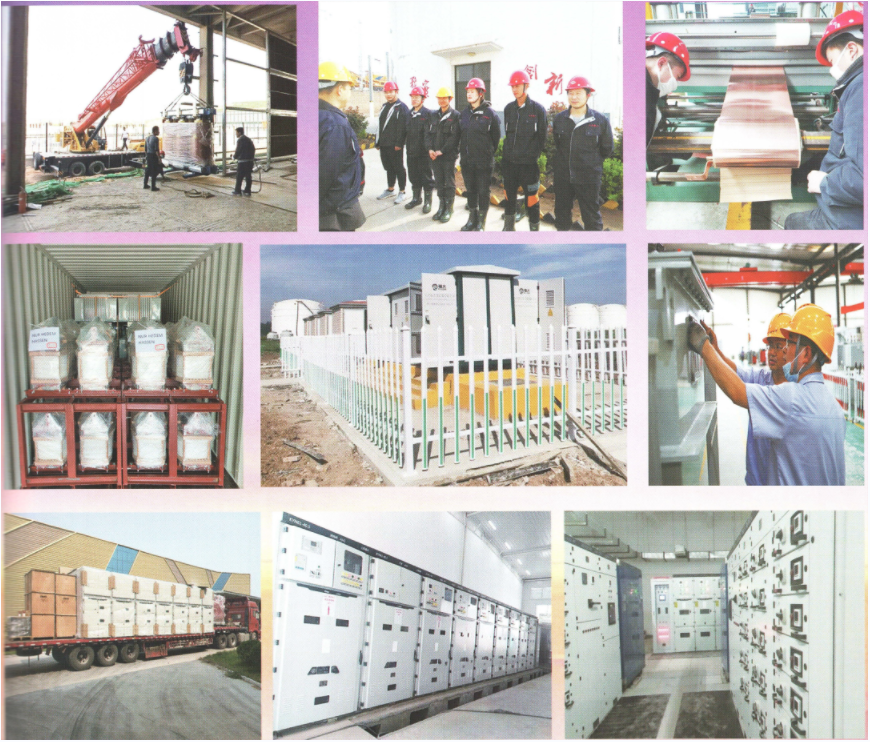

Professional Expertise

At Kunb Power, we leverage years of experience to design and manufacture single-phase transformers that meet the highest standards of performance, reliability, and efficiency. Our expert team ensures each transformer is crafted with precision, using quality materials for long-term stability in various applications.

Affordable Pricing

We offer highly competitive pricing for our single-phase transformers without compromising on quality. Through efficient manufacturing processes, we reduce costs, providing cost-effective solutions for both small and large projects.

After-Sales Support

Kunb Power is committed to customer satisfaction, offering comprehensive after-sales support, including installation guidance, maintenance services, and prompt troubleshooting. Our team ensures continuous performance, giving clients peace of mind.

Product Installation

1. Preparation

- Check the Equipment: Ensure all components are complete, including the transformer, oil tank, terminal connections, etc.

- Clean the Area: Choose an appropriate installation site with a level, dry surface, and clear surrounding area.

- Prepare Tools: Gather necessary tools, such as lifting equipment, screwdrivers, wrenches, pressure gauges, etc.

2. Lifting and Positioning

- Lift the Transformer: Carefully lift the transformer using lifting equipment, ensuring it is positioned vertically without any external force.

- Position the Transformer: Place the transformer on the designated platform or support frame, ensuring it is stable and meets the requirements specified in the manual.

3. Wiring Connections

- Main Cable Connections: Connect the input (high voltage) and output (low voltage) cables according to the transformer’s wiring diagram. Ensure all terminal connections are secure to prevent looseness.

- Grounding: Connect the grounding wire following the relevant standards to ensure proper grounding and safety.

- Connect Auxiliary Devices: If applicable, connect auxiliary devices such as temperature sensors or pressure release valves as per the requirements.

4. Oil Level Check and Filling

- Check Oil Level: Open the oil tank and check the oil level to ensure it is within the recommended range. Add transformer oil if the level is too low.

- Clean the Oil Tank: Inspect the oil tank to ensure it is clean and free from impurities, ensuring the oil’s insulation properties are maintained.

5. Electrical Testing and Commissioning

- Insulation Test: Use an insulation resistance tester to check the transformer’s insulation resistance, ensuring it meets safety standards.

- Initial Testing: Perform an unloaded test to verify oil level, temperature, and ensure no oil leakage or abnormal sounds.

6. Startup and Debugging

- Power On: After confirming correct wiring and insulation, connect the power and monitor the transformer’s current, voltage, and oil temperature to ensure stable operation.

- Load Test: Test the transformer under low load conditions to ensure it operates stably without any issues.

7. Operation Monitoring and Maintenance

- Regular Checks: Periodically inspect the transformer’s operating parameters such as oil level, temperature, voltage, etc., to ensure it is functioning properly.

- Maintenance: Perform necessary cleaning, maintenance, and oil changes according to the user manual

Certifications

Packing & Delivery

FAQ

1. Are you a trading company or a manufacturer?

Manufacturer with factory!

2. What kind of earthing materials do you produce?

Including ground rods, lightning rods, connection fixtures, conductors, exothermic welding kits, and more.

3. Do you offer customized materials?

Yes, please provide the specifications you need.

4.Do you accept OEM service?

Yes, we do!

5. What is your delivery time?

Usually 20-25 days, please confirm with us before ordering!

6.What is the payment method?

Usually, 50% as deposit and 50% by T/T before sending the bill of lading.

7.How do you pack the products?

Usually on steel pallets. We will pack according to customer's requirement.