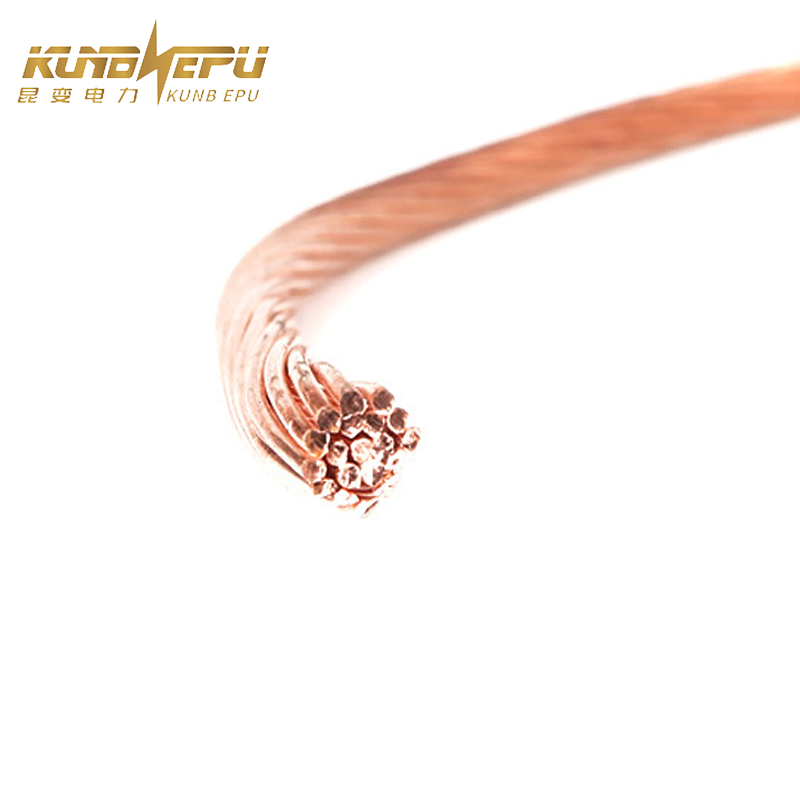

Kunb Power Contact Flexible Copper Stranded Wire

Kunbpower Flexible Copper Stranded Wire** is crafted using high-quality copper, designed for superior conductivity and durability. The wire consists of multiple fine copper strands, making it highly flexible and ideal for applications requiring frequent movement or bending. It provides excellent electrical performance and is resistant to corrosion, ensuring a long-lasting and efficient solution for electrical systems.

Description

Product Description

Kunbpower Flexible Copper Stranded Wire is crafted using high-quality copper, designed for superior conductivity and durability. The wire consists of multiple fine copper strands, making it highly flexible and ideal for applications requiring frequent movement or bending. It provides excellent electrical performance and is resistant to corrosion, ensuring a long-lasting and efficient solution for electrical systems.

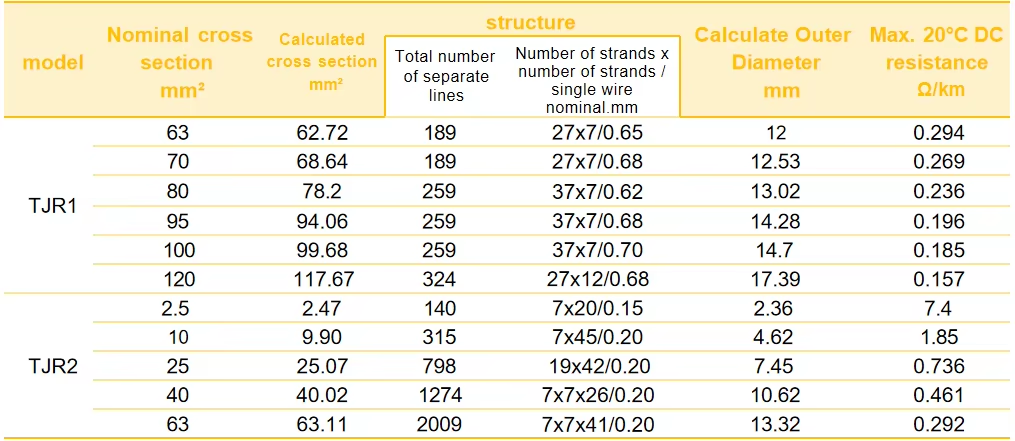

Product Parameter

Product Advantages

Product Advantages

-

High Conductivity: Made from pure copper, ensuring low resistance and high electrical performance.

- Flexible Design: Multiple stranded copper wires offer enhanced flexibility, making it perfect for tight spaces or dynamic environments.

- Durability: Corrosion-resistant and capable of withstanding wear and tear in challenging conditions.

- Versatile Applications: Ideal for use in automotive, industrial, power distribution, and electronics applications where flexibility and high performance are critical.

-

Applications:

- Power cables

- Automotive wiring

- Industrial machinery

- Electrical panels and circuits

Choose our Flexible Copper Stranded Wire for reliable and efficient electrical connections in any demanding application.

Product Installation

1. Preparation

Tools and equipment: Prepare the necessary tools, such as wire strippers, crimping tools, terminals, screwdrivers, insulating tape, retaining clips, etc.

Safety check: Bare copper stranded wires are not protected by insulation and extra care must be taken when installing them to ensure that there is no electrical hazard in the work area and that proper safety equipment, such as insulated gloves, is worn.

2. Wiring

Measurement and planning: Measure the length of stranded wire required according to actual demand and plan the wiring path. Try to avoid excessive bending of the line to avoid copper wire breakage.

Cleaning: Before installation, make sure the connector part of the bare copper stranded wire is clean and free of corrosion. If there is any oxidized layer, use a wire brush to gently clean the surface of the copper wire to ensure good conductivity.

3. Connection Method

Terminal connection: Bare copper stranded wire is usually connected by terminal or crimp connector. When using copper terminals, crimp the bare copper stranded wire into the terminal, making sure the crimp is secure and in full contact with the terminal.

Use of crimping tools: When using crimping tools, make sure that the copper wires are crimped tightly to avoid poor contact or overheating.

Avoid short-circuiting of exposed parts: Make sure that the contact surface of the copper wire is not in direct contact with other conductive materials or metal parts when connecting to avoid short-circuiting or electric shock.

4. Fixing and Protection

Fixing the soft copper stranded wire: Use suitable fixing clips or brackets to fix the bare copper stranded wire firmly in the required position. Avoid excessive stretching or bending of the wire when fixing.

Avoid contact between the exposed part and human body: Since the bare copper wire is not protected by insulation, avoid contact between the exposed part and human body during installation. The exposed portion can be wrapped with electrical insulating tape or prevented from contact by means of securing and shielding.

5. Insulation and protection

Corrosion protection: Bare copper stranded wire may oxidize when exposed to air for long periods of time. Therefore, it is recommended that bare copper wire be protected with corrosion resistant oil or protective sleeving (e.g., heat-shrinkable tubing), especially in outdoor environments.

Avoid contact with water or moisture: Bare copper stranded wires are sensitive to moisture and prone to corrosion, therefore, it should be ensured that the wires are not exposed to moisture during installation, especially in underground or outdoor environments.

6. Inspection and Testing

Electrical test: After the installation is completed, an electrical test is required to ensure that the joints and wiring are well connected, the current can pass through stably, and there are no loose or poor contact problems.

Final inspection: check all bare copper stranded wire connection points are tight, whether the line may be in contact with other conductive substances, to ensure that the entire installation process in line with electrical safety standards.

During the installation of bare copper stranded wire, it is important to pay extra attention to safety, especially during contact and installation, as bare copper wire is susceptible to short circuiting or electric shock.

If you have a specific installation environment or requirement, providing more details can help give more accurate installation advice.

Product Packing

All of our products are with strong packing and free of charge, we also can provide packing according to customer’s requirement.

Certifications

Packing & Delivery

FAQ

1. Are you a trading company or a manufacturer?

Manufacturer with factory!

2. What kind of earthing materials do you produce?

Including ground rods, lightning rods, connection fixtures, conductors, exothermic welding kits, and more.

3. Do you offer customized materials?

Yes, please provide the specifications you need.

4.Do you accept OEM service?

Yes, we do!

5. What is your delivery time?

Usually 20-25 days, please confirm with us before ordering!

6.What is the payment method?

Usually, 50% as deposit and 50% by T/T before sending the bill of lading.

7.How do you pack the products?

Usually on steel pallets. We will pack according to customer's requirement.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL ID

ID SR

SR SK

SK SL

SL UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS GA

GA CY

CY HY

HY BN

BN LA

LA UZ

UZ KY

KY