Kunb MV&HV Three Phase Dry Type Transformer

Three-phase transformers are widely used in circuits with AC 50Hz to 60Hz and voltage below 660V, and are widely used in important equipments, precision machine tools, mechanical and electronic equipments, medical equipments, rectification devices, lighting and so on. Products of various input and output voltage, connection group, adjust the number and position of the tap (generally ± 5%), the distribution of winding capacity, secondary single-phase winding equipment, the use of rectifier circuits, whether or not to require shell, etc., can be based on the user's requirements for the careful design and manufacture.

Description

Product Description

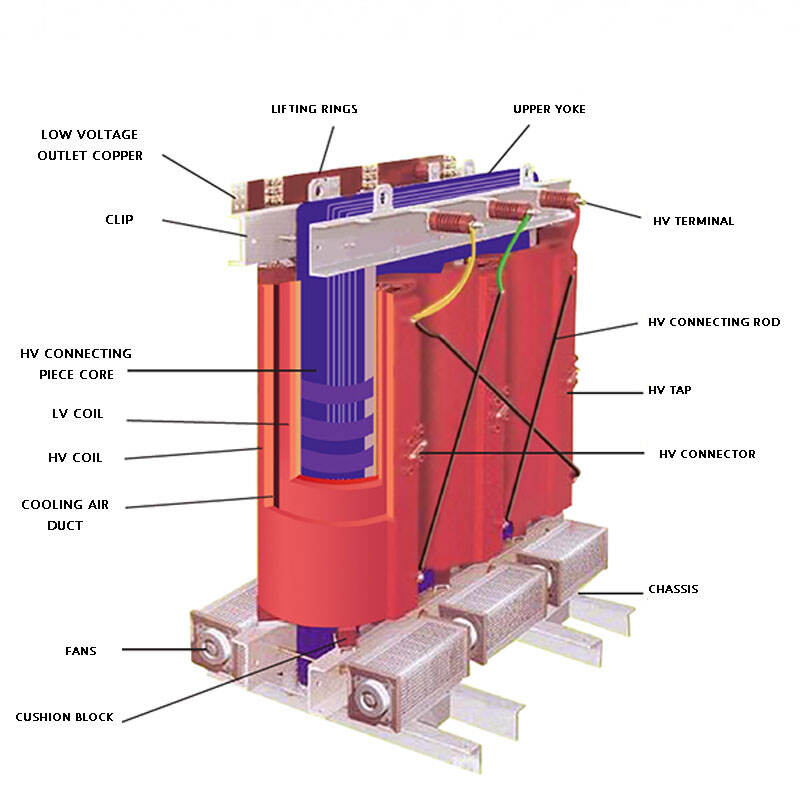

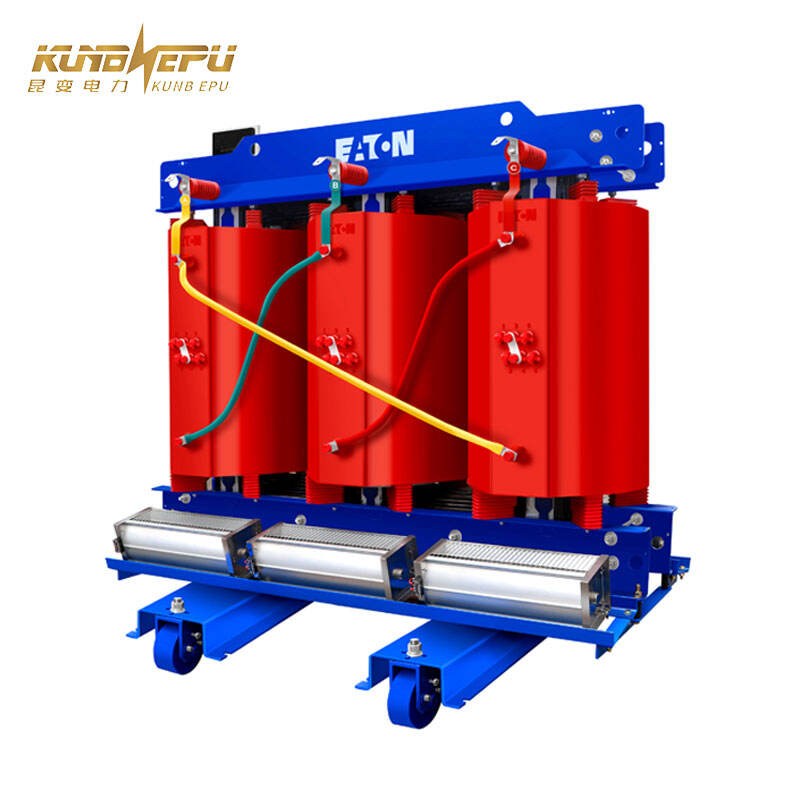

Kunbpower three-phase dry-type transformer is an efficient and reliable solution for voltage regulation in three-phase power systems. Its key advantages include improved safety, as it uses air cooling rather than oil, eliminating fire hazards. These transformers are low-maintenance, durable, and suitable for harsh environments. They also offer energy efficiency and compact design, making them ideal for commercial, industrial, and residential applications where space and safety are priorities.

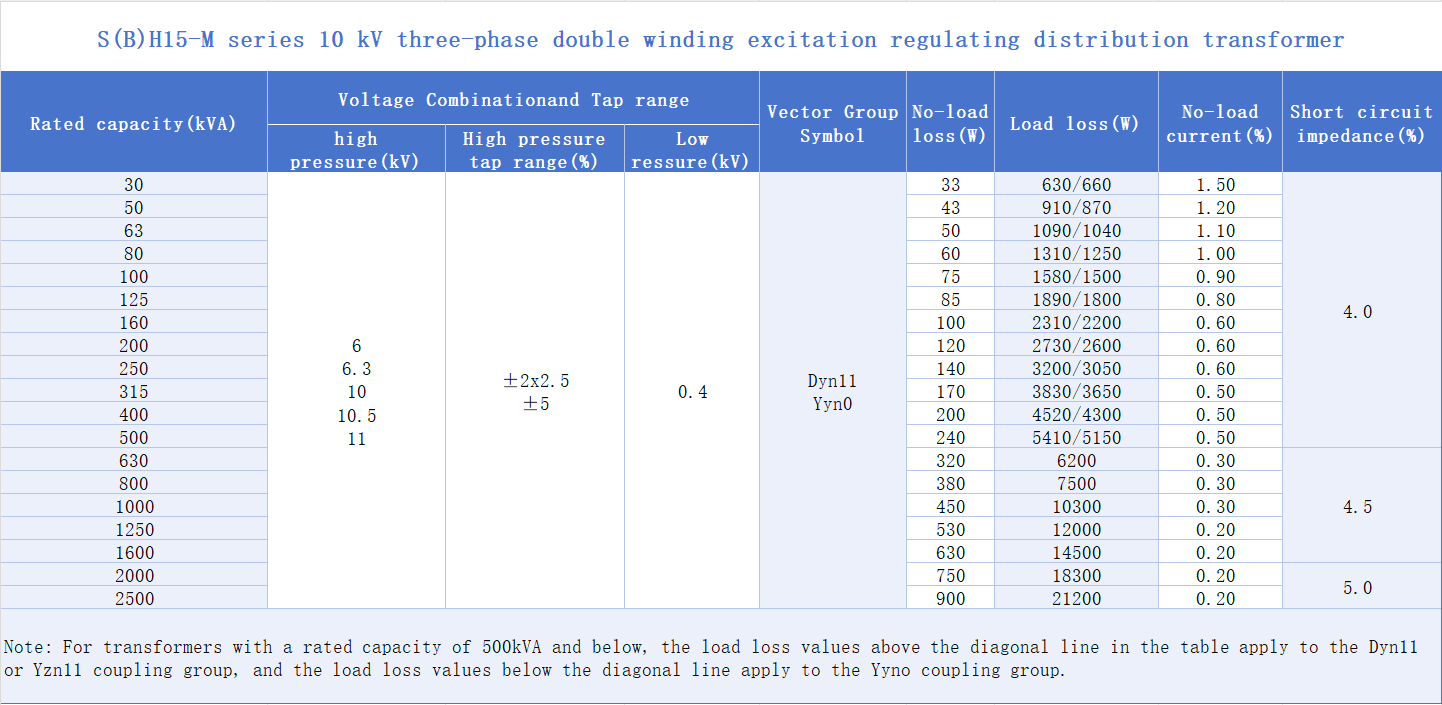

Product Parameter

Product Advantages

-

High Efficiency: Designed to provide stable and reliable voltage regulation, ensuring optimal performance in three-phase power systems.

Compact & Space-Saving: The dry-type design offers a smaller footprint, making it ideal for installations where space is limited.

Enhanced Safety: With air cooling and no oil, these transformers eliminate fire risks, offering a safer solution for commercial, industrial, and residential use.

Durability: Built to withstand harsh environments, these transformers are resistant to corrosion and require minimal maintenance, ensuring long-term reliability.Applications:

- Power distribution networks

- Industrial machinery

- Commercial buildings

- Renewable energy systems

Choose our Three-Phase Dry-Type Transformer for a safe, efficient, and durable solution to meet your voltage regulation needs.

Product Installation

-

Preparation

- Ensure the installation site is clean, dry, and properly ventilated.

- Verify that the foundation or platform can support the transformer’s weight and provide sufficient space for airflow and maintenance.

- Inspect the transformer for any visible damage during transportation.

-

Positioning the Transformer

- Place the transformer in the designated location, ensuring it's aligned with the input and output power lines.

- Ensure proper clearance around the transformer for ventilation and easy access for future maintenance.

-

Electrical Connections

- Connect the primary (input) and secondary (output) terminals to the corresponding power lines using appropriately sized cables.

- Ensure all connections are tight and secure to prevent any electrical faults.

- Use appropriate grounding techniques to connect the transformer to the grounding system, ensuring proper earthing to avoid electrical hazards.

-

Cooling System Setup

- Verify that the cooling system (air ventilation) is installed and functioning properly, ensuring that the transformer operates within its rated temperature range.

- Ensure the transformer’s air circulation is not obstructed, allowing for efficient heat dissipation.

-

Testing and Commissioning

- Perform insulation resistance tests to ensure the transformer’s insulation is intact.

- Check all connections for proper torque and tightness.

- Power up the system and check for proper voltage output and functionality.

- Monitor the transformer’s temperature and load during initial operation.

-

Final Inspection and Safety Check

- Ensure all safety mechanisms, such as circuit breakers and fuses, are in place and functioning correctly.

- Verify that the installation complies with all local electrical codes and safety regulations.

- Document the installation and perform a final inspection.

-

Training and Handover

- Provide training for operators and maintenance personnel on safe operation and routine maintenance procedures.

- Handover the installation to the relevant personnel for continuous operation.

This process should be adjusted based on specific site conditions and manufacturer guidelines. Let me know if you need further details!

Certifications

Packing & Delivery

FAQ

1. Are you a trading company or a manufacturer?

Manufacturer with factory!

2. What kind of earthing materials do you produce?

Including ground rods, lightning rods, connection fixtures, conductors, exothermic welding kits, and more.

3. Do you offer customized materials?

Yes, please provide the specifications you need.

4.Do you accept OEM service?

Yes, we do!

5. What is your delivery time?

Usually 20-25 days, please confirm with us before ordering!

6.What is the payment method?

Usually, 50% as deposit and 50% by T/T before sending the bill of lading.

7.How do you pack the products?

Usually on steel pallets. We will pack according to customer's requirement.