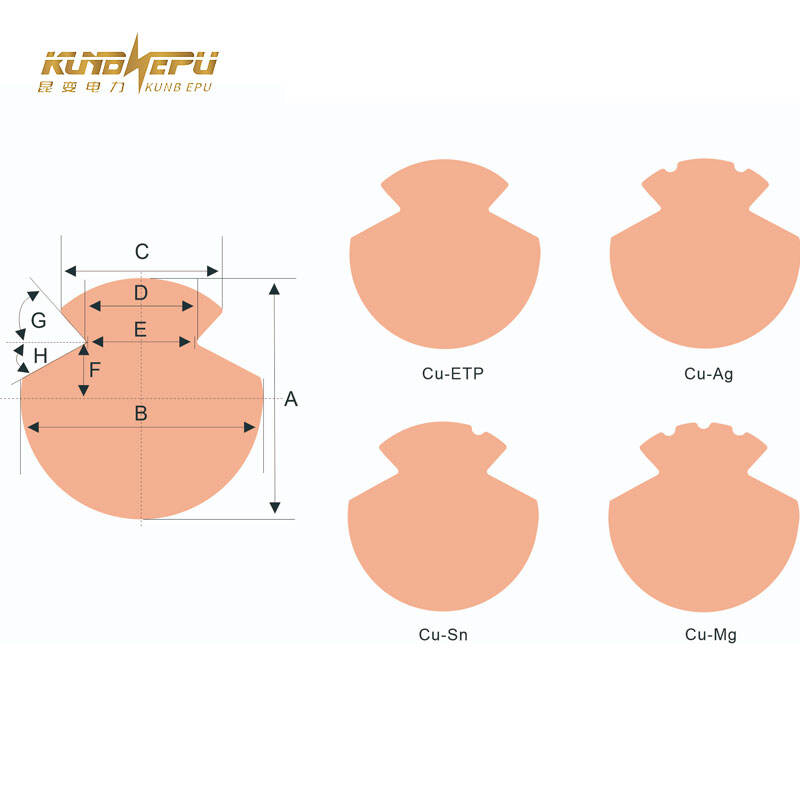

Kunb Power Contact Copper-Tin Alloy Contact Wire

Copper-tin alloy contact wire is a high-performance conductor made by combining copper with a small percentage of tin. This alloy enhances the wire's resistance to corrosion, wear, and high temperatures, making it ideal for use in railway electrification systems. It offers excellent conductivity and mechanical strength, ensuring reliable power transmission and durability in demanding environments. With superior resistance to oxidation and longer service life, copper-tin alloy contact wire is a cost-effective solution for high-performance rail systems.

Description

Product Description

Our Copper-Tin Alloy Contact Wire combines superior electrical conductivity with enhanced corrosion resistance, making it an ideal choice for railway electrification systems. Manufactured with high-quality materials, our contact wires offer excellent durability and long-lasting performance in harsh environments. We provide these products at competitive prices without compromising quality. With reliable after-sales support, we ensure our customers receive both value and peace of mind with every purchase.

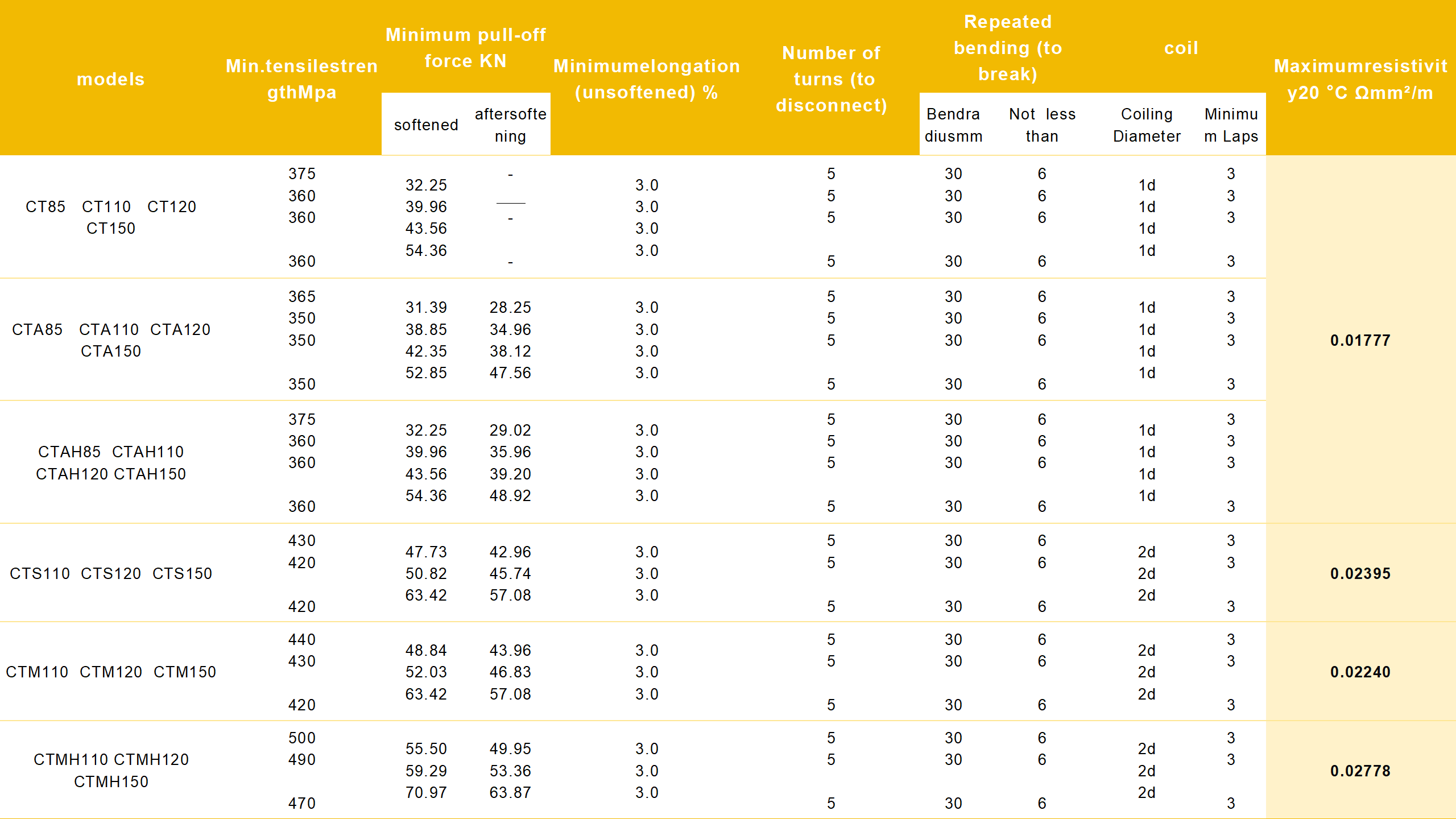

Product Parameter

Product Advantages

-

High-Performance Copper-Tin Alloy Contact Wire

- Superior Conductivity: Made from a copper-tin alloy, offering excellent electrical conductivity for reliable power transmission.

- Enhanced Durability: The addition of tin improves corrosion resistance and wear resistance, ensuring longer service life in demanding environments.

- High Strength: Provides strong mechanical properties, capable of withstanding high temperatures and mechanical stress.

- Versatile Applications: Ideal for use in railway electrification systems, overhead power lines, and other high-performance energy transmission applications.

Applications:

- Railway electrification

- Overhead power lines

- High-performance energy transmission systems

Choose our Copper-Tin Alloy Contact Wire for efficient, durable, and cost-effective power transmission in even the most challenging environments.

Product Installation

1. Applications Overview

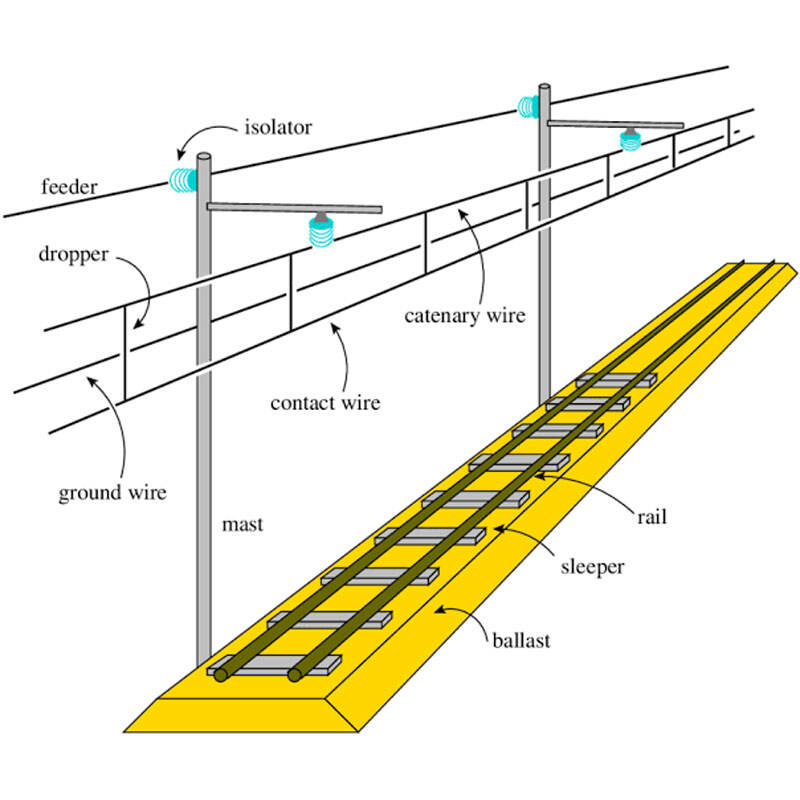

Copper-tin alloy contact wire is primarily used in railway electrification systems, where it serves as the primary conductor for supplying electricity to trains. The alloy's corrosion resistance and excellent conductivity make it ideal for use in overhead contact lines (OCL), ensuring efficient power transmission while withstanding the physical and environmental challenges faced in railway operations.

Key Applications:

- Railway Electrification: Used in overhead catenary systems for electric trains, ensuring a stable power supply.

- Tram Systems: Employed in the electrification of trams and light rail systems.

- High Voltage Power Lines: Suitable for use in urban or industrial power transmission, where mechanical strength and electrical performance are crucial.

2. Installation Guidelines

Proper installation of copper-tin alloy contact wire is essential for its optimal performance. Here are some key points to follow during installation:

-

Tensioning: Copper-tin alloy contact wire must be installed with the correct tension to ensure reliable operation. Excessive tension can cause wear and damage, while too little tension can lead to sagging and unreliable power transmission. Always follow the manufacturer’s guidelines for tensioning.

-

Height and Alignment: Ensure that the contact wire is installed at the correct height and alignment relative to the railway track. Consistent distance between the contact wire and the pantograph (the device that collects electricity from the wire) is necessary for stable power transfer.

-

Connection to Catenary: The copper-tin alloy contact wire should be securely connected to the catenary system. Properly designed connectors and clamps should be used to maintain continuous electrical contact and prevent the wire from becoming loose during operation.

3. Maintenance Tips

To maximize the lifespan and performance of copper-tin alloy contact wire, regular maintenance is essential:

-

Routine Inspections: Inspect the wire regularly for any signs of wear, oxidation, or physical damage. The copper-tin alloy's corrosion resistance is strong, but environmental factors such as humidity, salt, and pollution can accelerate deterioration.

-

Cleaning: If the wire is exposed to dust or debris, it should be cleaned periodically to maintain efficient electrical conductivity. Use non-abrasive cleaning methods to avoid damaging the copper-tin coating.

-

Check for Loose Connections: Over time, clamps and connectors may loosen due to mechanical vibrations. Tighten these connections as part of routine maintenance to prevent power loss and ensure system reliability.

4. Advantages of Copper-Tin Alloy Contact Wire

The unique properties of copper-tin alloy make it particularly suited for railway and power transmission systems:

-

Corrosion Resistance: The tin content in the alloy significantly enhances the wire's resistance to corrosion, especially in harsh environments such as coastal areas or regions with high pollution.

-

High Strength: Copper-tin alloy offers superior mechanical strength, ensuring the wire can handle the tension and physical stress in overhead contact lines.

-

Long Service Life: Due to its durability and corrosion resistance, copper-tin alloy contact wire has a longer service life compared to standard copper wires, reducing the frequency of replacements and lowering long-term maintenance costs.

-

Efficient Power Transmission: The copper component ensures excellent electrical conductivity, allowing for efficient power transmission even over long distances.

Product Packing

All of our products are with strong packing and free of charge, we also can provide packing according to customer’s requirement.

Certifications

Packing & Delivery

FAQ

1. Are you a trading company or a manufacturer?

Manufacturer with factory!

2. What kind of earthing materials do you produce?

Including ground rods, lightning rods, connection fixtures, conductors, exothermic welding kits, and more.

3. Do you offer customized materials?

Yes, please provide the specifications you need.

4.Do you accept OEM service?

Yes, we do!

5. What is your delivery time?

Usually 20-25 days, please confirm with us before ordering!

6.What is the payment method?

Usually, 50% as deposit and 50% by T/T before sending the bill of lading.

7.How do you pack the products?

Usually on steel pallets. We will pack according to customer's requirement.