Kunb Enameled Copper Wire For Motor Windings

Kunb power enameled copper wire is a type of magnet wire coated with a thin layer of insulation, providing excellent electrical conductivity and high resistance to heat. Made from high-quality copper, it ensures low resistance and superior performance in various applications. Commonly used in motors, transformers, inductors, and other electrical devices, it offers durability, flexibility, and efficient energy transfer. The wire’s insulation protects against short circuits and environmental damage, ensuring long-term reliability

Description

Product Description

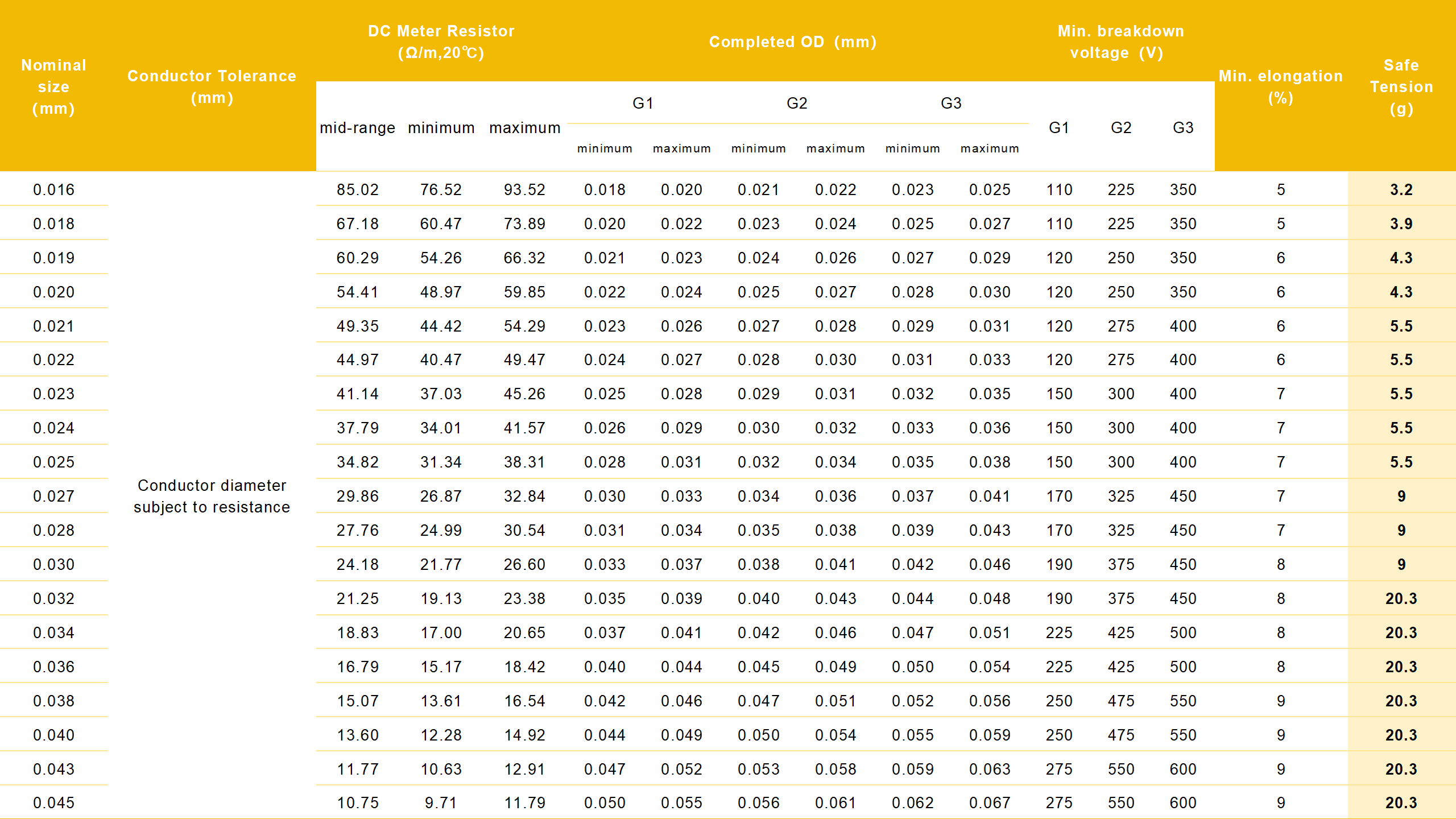

Kunb power enameled copper wire comes in a variety of common specifications to meet diverse needs. Popular gauges include 0.1mm to 5mm, ideal for applications in motors, transformers, and electrical equipment. Made from high-quality copper, our wires offer excellent conductivity, superior insulation, and reliable performance. Not only is our product priced competitively, ensuring cost savings, but it also maintains high standards of quality and durability. Plus, we offer robust after-sales support to ensure customer satisfaction and long-term reliability.

Product Parameter

Product Advantages

- High Conductivity: Made from high-purity copper, ensuring low resistance and optimal electrical performance for efficient power transfer.

- Excellent Insulation: Coated with a thin layer of enamel, offering superior insulation and preventing short circuits.

- Durability: The enamel coating provides excellent protection against wear, heat, and environmental damage, ensuring long-term reliability.

- Versatile Applications: Ideal for use in motors, transformers, inductors, electrical coils, and other precision electrical equipment, where high performance and durability are essential.

Applications:

- Motors and generators

- Transformers and inductors

- Electrical coils and solenoids

- Home appliances and electrical equipment

Choose our Enameled Copper Wire for superior conductivity, reliable insulation, and long-lasting performance in any high-demand electrical application.

Product Installation

-

Preparation:

Ensure the work area is clean and dry. Gather the necessary tools, such as wire cutters, stripping tools, and a soldering iron. Measure and cut the required length of enameled copper wire. -

Wire Stripping:

Use a wire stripper or a sharp blade to carefully remove the enamel coating from the wire ends. Be cautious to avoid damaging the copper wire itself. For thin wires, use a specialized stripping tool to prevent breakage. -

Soldering or Connecting:

Once stripped, apply a small amount of solder to the exposed copper ends for secure connections. Use the wire for winding coils, connecting to electrical components, or assembling circuits as needed. Ensure good electrical contact between the wire and the components. -

Coiling and Winding:

If using the wire for coils or winding (e.g., transformers or motors), carefully wind the wire around the core. Keep the turns neat and spaced consistently. Avoid excessive tension to prevent wire breakage. -

Insulation and Protection:

After use, ensure the wire’s exposed sections are insulated, especially when connecting to high-voltage circuits. Use heat shrink tubing, insulating tape, or resin to protect the wire ends from external damage. -

Testing:

After installation, conduct electrical tests to ensure the circuit functions properly. Check for any loose connections or shorts.

Product Packing

All of our products are with strong packing and free of charge, we also can provide packing according to customer’s requirement.

Certifications

Packing & Delivery

FAQ

1. Are you a trading company or a manufacturer?

Manufacturer with factory!

2. What kind of earthing materials do you produce?

Including ground rods, lightning rods, connection fixtures, conductors, exothermic welding kits, and more.

3. Do you offer customized materials?

Yes, please provide the specifications you need.

4.Do you accept OEM service?

Yes, we do!

5. What is your delivery time?

Usually 20-25 days, please confirm with us before ordering!

6.What is the payment method?

Usually, 50% as deposit and 50% by T/T before sending the bill of lading.

7.How do you pack the products?

Usually on steel pallets. We will pack according to customer's requirement.