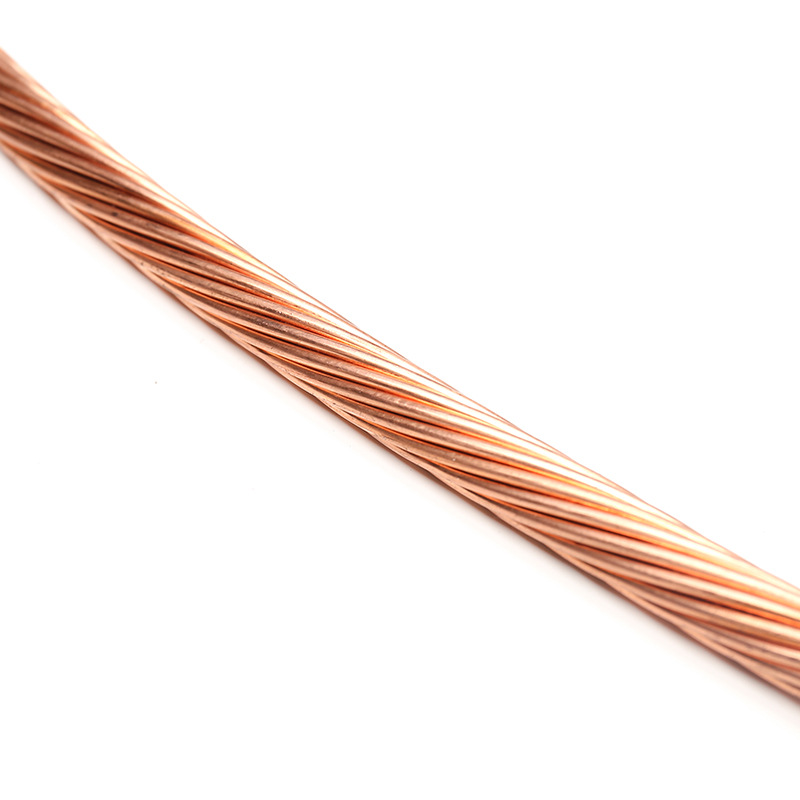

Kunb Copper-Magnesium Alloy Stranded Wire

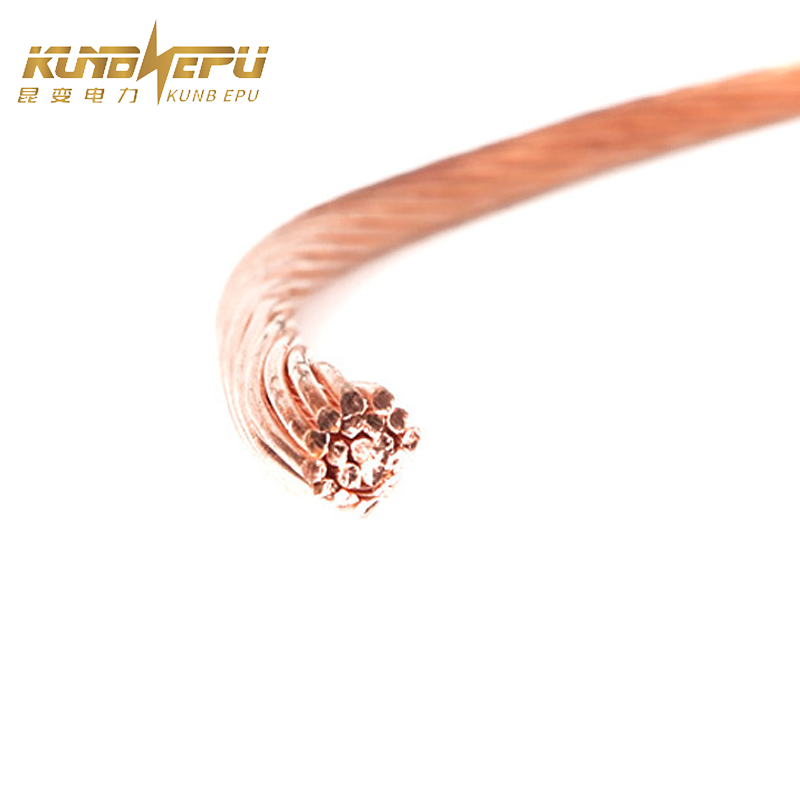

Copper-magnesium alloy stranded wire is a high-performance conductor made by combining copper with magnesium, enhancing the wire’s strength and electrical conductivity. The addition of magnesium improves the wire's resistance to wear, corrosion, and high temperatures, making it ideal for use in demanding environments. This wire is commonly used in power transmission, electrical distribution, and automotive applications where both conductivity and mechanical strength are essential for reliable and long-lasting performance.

Description

Product Description

Our Copper-Magnesium Alloy Stranded Wire offers excellent electrical conductivity and mechanical strength at a competitive price. The copper-magnesium alloy combines superior conductivity with enhanced resistance to wear, corrosion, and high temperatures. It is ideal for power transmission, electrical distribution, and automotive applications. With a focus on high performance and cost-effectiveness, we ensure quality products backed by reliable after-sales support, providing peace of mind with every purchase.

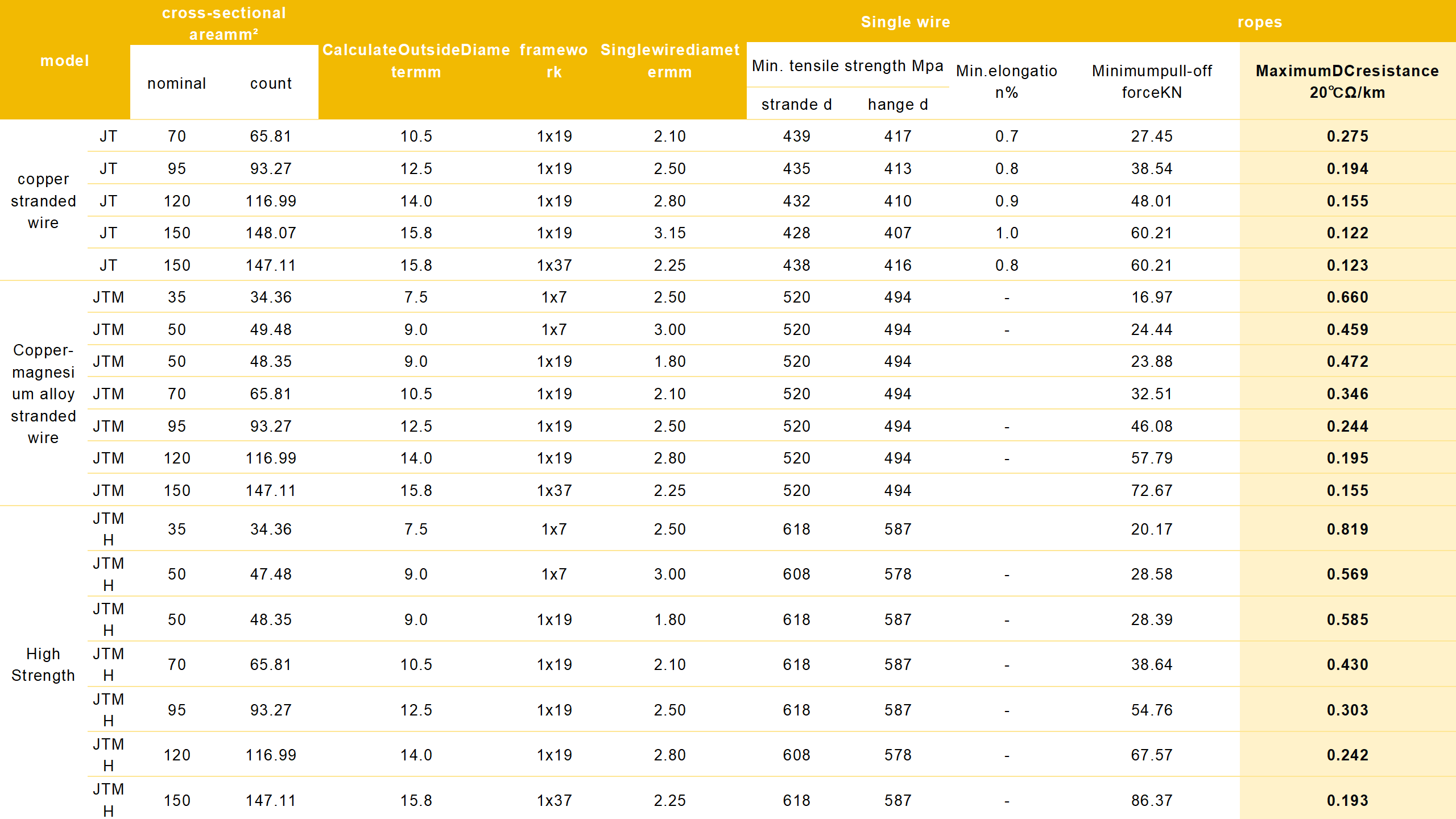

Product Parameter

Product Advantages

-

High-Performance Copper-Magnesium Alloy Stranded Wire

- High Conductivity: Made from copper-magnesium alloy, offering excellent electrical conductivity for reliable power transmission.

- Enhanced Strength: Magnesium content boosts the mechanical strength, ensuring durability in high-stress applications.

- Corrosion Resistance: Designed to withstand corrosion, providing long-lasting performance in harsh environments.

- Versatile Applications: Ideal for use in power transmission, automotive, electrical distribution, and industrial systems where both conductivity and strength are crucial.

Applications:

- Power cables

- Automotive wiring

- Electrical distribution systems

- Industrial machinery

Choose our Copper-Magnesium Alloy Stranded Wire for reliable and efficient electrical connections in demanding environments.

Product Installation

1. Applications Overview

Copper-magnesium alloy stranded wire is used in various industries where both electrical conductivity and mechanical strength are essential. Some of the main applications include:

- Power Transmission: It is used in power lines and electrical distribution systems for transmitting electrical energy over long distances.

- Automotive Wiring: The wire is utilized in automotive electrical systems due to its flexibility, strength, and resistance to heat and corrosion.

- Industrial Machinery: It is commonly used in machinery that requires high-strength, durable electrical wiring.

- Electrical Panels and Circuits: The wire is also suitable for use in electrical panels and circuits that need efficient power conduction with minimal loss.

2. Installation Guidelines

For optimal performance and longevity of copper-magnesium alloy stranded wire, proper installation is crucial:

-

Tensioning: Copper-magnesium alloy stranded wire should be installed with appropriate tension to prevent sagging or excessive strain. Ensure that the wire is not under too much tension, as this could cause premature wear or breakage. Always follow the manufacturer's tensioning specifications.

-

Routing and Placement: Route the wire in a way that avoids sharp bends or angles, as these can cause stress on the wire and impact its electrical performance. When installing in tight spaces or conduits, ensure that the wire is not bent beyond its minimum bending radius.

-

Connection to Components: Use proper connectors, clamps, and terminals that are compatible with copper-magnesium alloy wire. Make sure that all connections are secure and free from corrosion, as this can lead to poor electrical conductivity and safety hazards.

3. Maintenance Tips

Regular maintenance is key to ensuring the copper-magnesium alloy stranded wire performs optimally throughout its life:

-

Visual Inspections: Periodically inspect the wire for signs of damage, wear, or corrosion, especially in harsh environments. If any issues are found, replace the damaged sections to maintain system integrity.

-

Cleaning: Clean the wire as needed, especially in areas where dust, dirt, or other contaminants may affect performance. Use non-abrasive materials to avoid damaging the wire’s surface.

-

Monitor for Corrosion: While the magnesium alloy offers resistance to corrosion, it is still important to monitor the wire, especially in humid, salty, or chemically reactive environments. If corrosion is detected, inspect and repair any compromised connections.

4. Advantages of Copper-Magnesium Alloy Stranded Wire

Copper-magnesium alloy stranded wire offers numerous advantages, making it a preferred choice in various electrical applications:

-

High Conductivity: The copper core ensures excellent electrical conductivity, allowing efficient power transmission and reduced energy loss.

-

Enhanced Strength: The magnesium component strengthens the wire, providing durability and resistance to physical stress, which is essential in high-demand environments like automotive or industrial machinery.

-

Corrosion Resistance: The alloy's resistance to corrosion ensures the wire performs reliably even in outdoor, high-humidity, or chemically exposed areas.

-

High-Temperature Resistance: Copper-magnesium alloy stranded wire can withstand elevated temperatures, making it suitable for high-heat applications.

Product Packing

All of our products are with strong packing and free of charge, we also can provide packing according to customer’s requirement.

Certifications

Packing & Delivery

FAQ

1. Are you a trading company or a manufacturer?

Manufacturer with factory!

2. What kind of earthing materials do you produce?

Including ground rods, lightning rods, connection fixtures, conductors, exothermic welding kits, and more.

3. Do you offer customized materials?

Yes, please provide the specifications you need.

4.Do you accept OEM service?

Yes, we do!

5. What is your delivery time?

Usually 20-25 days, please confirm with us before ordering!

6.What is the payment method?

Usually, 50% as deposit and 50% by T/T before sending the bill of lading.

7.How do you pack the products?

Usually on steel pallets. We will pack according to customer's requirement.