Korrekt installation af jordstænger er afgørende for at sikre, at dit elektriske system er sikkert og pålideligt. Uanset om du vælger en kobberslebet stang, galvaniseret jordstang , eller kobberplaceret støbestang , vil følge den korrekte installationsprocedure hjælpe med at forhindre elektriske farer og sikre optimal systemydelse. Denne vejledning giver 11 enkle trin til succesfuld installation af jordstænger.

1. Vælg den rigtige jordstang

Det første trin i installationen af en jordingsstang er at vælge den passende type til dine behov. Kobberjordstænger giver fremragende ledningsevne i fugtige miljøer, mens galvaniserede jordstænger er mere velegnede til tørre forhold på grund af deres modstandsdygtighed over for korrosion. Hvis du leder efter både holdbarhed og ledningsevne, en kobberbeklædt jordstang eller kobbermuldstang kan være ideelt. For mere information om valg af de rigtige jordstænger, besøg kunbpower.com .

2. Saml de nødvendige værktøjer og materialer

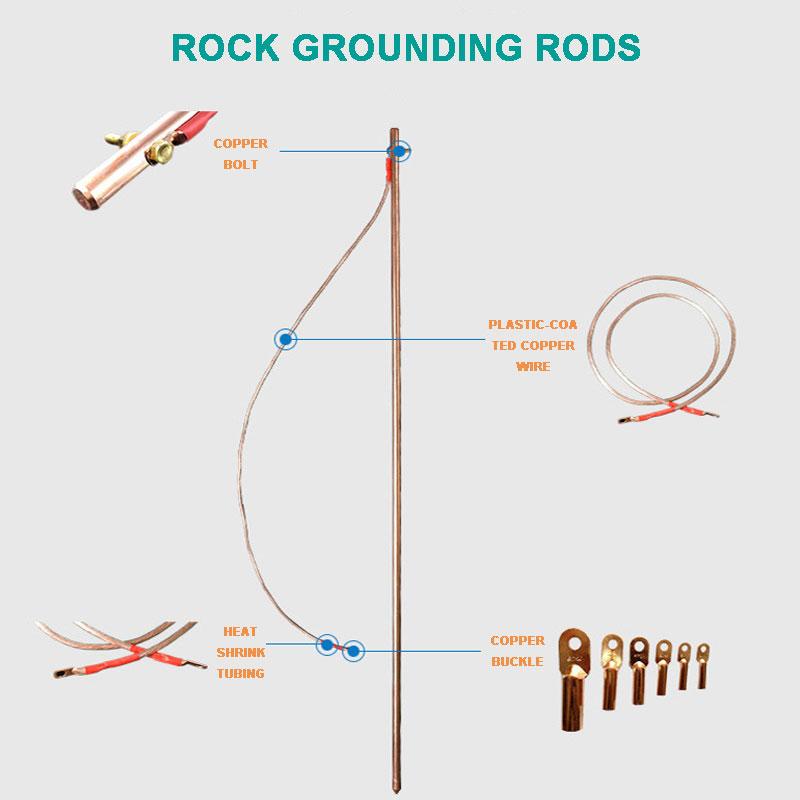

Inden du starter, skal du samle følgende værktøjer og materialer:

- Jordstang (såsom 8 fod kobberjordstænger, 5/8 jordstænger eller kobberstang til jording)

- Jordledning (vælg mellem kobber eller fortinnet afhængigt af din placering)

- Jordingsklemme til at fastgøre ledningen til jordingsstangen

- En hammer eller jordstangsdriver til at installere stangen

3. Tjek lokale regler

Det er vigtigt at verificere eventuelle lokale elektriske koder, før du installerer en jordstang. Forskrifter kan specificere den påkrævede type stang, installationsdybde og materiale. Sørg for at følge disse regler for at undgå problemer under inspektioner. For eksempel kan det være nødvendigt at bruge en galvaniseret jordingsstang eller rustfrit stål jordstang afhængigt af dine lokale standarder.

4. Vælg installationsstedet

Det ideelle sted for din jordstang er normalt i nærheden af det elektriske panel, men det bør være fri for store sten, trærødder eller andre forhindringer. Sørg for, at jordingsstangen er installeret i jord, der vil have god kontakt med jorden. Hvis du bruger en kobberjordingsstang, skal den være mindst 8 fod lang, men dette kan variere afhængigt af dine lokale krav.

5. Klargør jorden

Når du har valgt en placering, skal du forberede jorden ved at fjerne snavs eller store sten, der kan forstyrre installationen. Du skal muligvis grave et lille hul, hvis du installerer stangen manuelt. Hvis du bruger en jordstangsdriver, vil dette trin være hurtigere og mere effektivt.

6. Installer jordstangen

Det er tid til at installere jordstangen. Uanset om du bruger en hammer eller en jordstangsdriver, skal du forsigtigt køre stangen ned i jorden. Hvis du bruger en 8 fod kobberjordstang, skal du sørge for, at den er helt indlejret i jorden. Kobberbeklædte stålslebne stænger er særligt holdbare og fungerer godt i fugtige eller korrosive miljøer, hvilket gør dem til et fremragende valg til langtidsinstallationer.

7. Fastgør jordingsledningen

Når jordstangen er på plads, er det tid til at fastgøre jordledningen. Fastgør ledningen til stangen ved hjælp af en jordingsklemme. Sørg for, at forbindelsen er tæt for at undgå elektrisk lækage. En løs forbindelse kan føre til sikkerhedsrisici, så det er vigtigt, at ledningen er solidt fastgjort til kobberjordingsstangen.

8. Tilslut jordledningen til det elektriske panel

Tag den anden ende af jordingsledningen og fastgør den til jordforbindelsen i dit elektriske panel. Dette trin fuldender kredsløbet, hvilket tillader elektriske fejl eller overspændinger at strømme sikkert ind i jorden gennem jordkobberstangen. Sørg for, at ledningen er forsvarligt fastgjort og fri for skader.

9. Test jordingssystemet

Når alt er installeret, skal du bruge en jordmodstandstester til at kontrollere modstanden mellem jordstangen og jorden. Et godt jordforbindelsessystem vil have lav modstand, så den elektriske energi kan flyde frit ned i jorden. Hvis modstanden er høj, skal du muligvis justere stangens dybde eller installere yderligere jordstænger.

10. Sikre alle forbindelser

Dobbelttjek alle forbindelser for at sikre, at de er sikre. Hvis du har brugt en kobberjordingsstang, skal du sikre dig, at forbindelsen er tæt og fri for korrosion. For ekstra beskyttelse i fugtige miljøer bør du overveje at bruge en galvaniseret jordstang eller en jordstang i rustfrit stål, som giver overlegen modstandsdygtighed over for fugt og korrosion.

11. Udfør en sidste kontrol

Efter at have sikret alle forbindelser og fuldført opsætningen, skal du udføre en sidste inspektion af dit system. Sørg for, at der ikke er løse forbindelser, og at alt er korrekt installeret. Hvis du bor i et område med høje fugtniveauer, kan du overveje at tilføje flere galvaniserede jordstænger eller rustfri stålstænger for at forbedre systemets ydeevne. For yderligere vejledning om jordingsløsninger af høj kvalitet, besøg www.kunbpower.com

Konklusion

Installation af en jordstang er en vigtig opgave for at sikre sikkerheden af dit elektriske system. Uanset om du vælger en kobberjordstang, galvaniseret jordstang eller en kobberbeklædt ståljordstang, vil følgende enkle trin hjælpe dig med at skabe et sikkert og pålideligt jordingssystem. For mere information om jordstænger, jordingssystemer og relaterede produkter, besøg www.kunbpower.com

Indholdsfortegnelse

- 1. Vælg den rigtige jordstang

- 2. Saml de nødvendige værktøjer og materialer

- 3. Tjek lokale regler

- 4. Vælg installationsstedet

- 5. Klargør jorden

- 6. Installer jordstangen

- 7. Fastgør jordingsledningen

- 8. Tilslut jordledningen til det elektriske panel

- 9. Test jordingssystemet

- 10. Sikre alle forbindelser

- 11. Udfør en sidste kontrol