Copper clad steel grounding rod is a 3.0 four-dimensional plating process, in the surface treated mild steel core through the solution covered with 99.9% purity of electrolytic copper made of copper plating layer and steel in the form of molecules tightly bonded, with good electrical conductivity and strong corrosion resistance.

Copper clad steel conductors have comparable performance to bare copper in grounding applications and, due to their longer service life, have higher performance than galvanized steel in lightning protection.

Copper clad steel grounding rod features

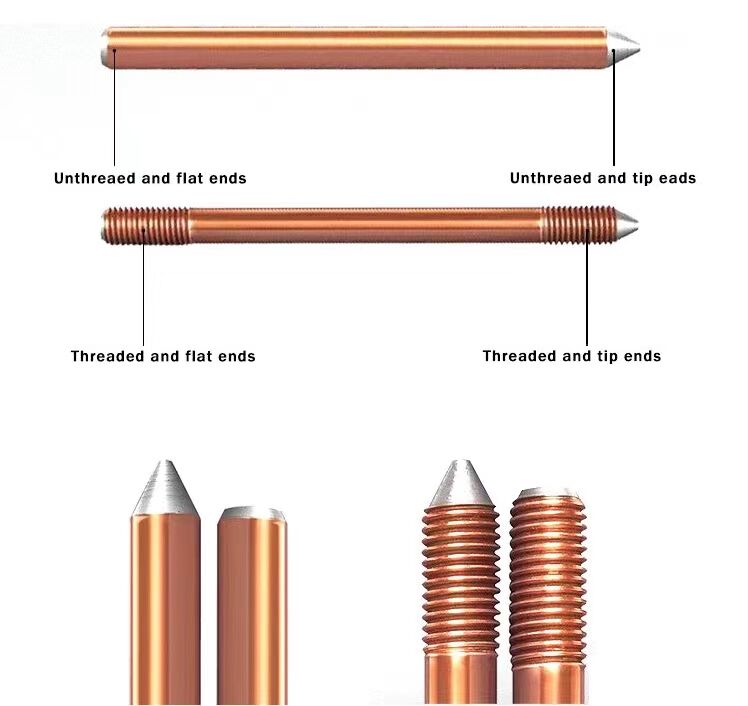

1.By the solid low-carbon steel core through the electroplating process covered with a uniform electrolytic copper layer (minimum 254 microns), copper and steel is a combination between the molecules, according to the principle of skin effect, both with copper's good electrical conductivity, but also with the mechanical strength of steel.

2.The material used in the mild steel core has a tensile strength of up to 600N/mm, thus it can be installed to a considerable depth with the aid of an impact hammer.

3. Grounding rod end threads are in the copper-plating process after rolling and become, steel and copper layer together with rolling in the threads, so that the threads at the steel and copper combination of exceptionally strong.

4.Copper clad steel composite conductor has higher current carrying capacity compared with copper of the same cross-section.

5.Copper clad steel composite conductor with the same cross-section of copper compared with a higher breaking strength.

6.Strong corrosion resistance. Ideal for harsh climates and environments.

7.Prevents theft. As copper and steel are molecularly bonded, making it difficult to separate between copper and steel, there is no value in theft.